franklin electric control box manual

Franklin Electric control boxes are designed for 3-wire, single-phase submersible motors, offering essential control and protection for optimal performance in water systems and industrial applications.

Overview of Franklin Electric Control Boxes

Franklin Electric control boxes are engineered to optimize performance and protection for submersible motor systems. Designed for 3-wire, single-phase motors, these control boxes are available in Standard and Deluxe models, catering to a wide range of applications, from residential water systems to industrial settings. They are compatible with motors rated from 1/3 to 15 horsepower and 230 volts. The control boxes feature essential components such as starting capacitors, overload protectors, and terminal blocks, ensuring reliable operation and system protection. Both models support standard or heavy-duty pressure switches, level switches, or other pilot devices. The Deluxe version includes advanced features like surge protection and higher-grade components for enhanced durability. These control boxes are integral to Franklin Electric’s submersible motor systems, providing a centralized interface for power management and system control. Their design ensures ease of installation, maintenance, and troubleshooting, making them a critical component for efficient water pumping solutions.

Importance of the Control Box in Submersible Motor Systems

The control box is a vital component in submersible motor systems, acting as the central hub for power management and system protection. It ensures the motor operates within safe parameters by regulating power supply and monitoring performance. The control box houses essential components like capacitors, overload protectors, and relays, which are crucial for starting and running the motor efficiently. It protects the motor from voltage fluctuations, overheating, and overloads, preventing damage and extending system lifespan. Additionally, the control box provides a safe and convenient interface for installation, troubleshooting, and maintenance. Without a properly functioning control box, the motor system could face frequent failures, reduced efficiency, and safety hazards. Thus, the control box is indispensable for reliable and efficient operation of Franklin Electric submersible motor systems in various applications, including water pumping and industrial processes.

Key Features of Franklin Electric Control Boxes

Franklin Electric control boxes are engineered with advanced features to ensure optimal performance and durability in submersible motor systems. They are designed for 3-wire, single-phase motors, offering compatibility with a wide range of horsepower ratings from 1/3 to 15 HP. These control boxes feature voltage ratings of 230V, making them suitable for various water pumping and industrial applications. They include essential components such as starting capacitors, overload protectors, and potential relays to ensure smooth motor operation. The units are equipped with durable enclosures that provide protection against environmental factors, ensuring reliable performance in harsh conditions. Additionally, Franklin Electric control boxes are designed for easy installation and maintenance, with clear wiring connections and accessible components. They also incorporate surge protection and proper grounding features to safeguard against voltage spikes and electrical hazards. These control boxes are a critical component for ensuring efficient and safe operation of submersible motor systems.

Installation and Wiring

Installation involves mounting the control box, connecting motor and power wires, and ensuring proper grounding. Follow wiring diagrams for 3-wire motors and adjust timeout settings as needed.

Step-by-Step Installation Guide

Begin by selecting a suitable location for the control box, ensuring easy access and protection from environmental elements. Mount the unit securely using the provided hardware. Next, connect the power supply wires to the designated terminals, ensuring all connections are tight and correct. Then, attach the motor wires according to the wiring diagram specific to your 3-wire setup. Properly ground the system to prevent electrical hazards. After wiring, replace the control box cover and apply the “Protected by Pumptec” label. Finally, test the system by running the motor through a full cycle to ensure proper operation. Always refer to the Franklin Electric AIM manual for detailed instructions and safety precautions. This guide ensures a safe and efficient installation process.

Wiring Diagrams for 3-Wire Motors

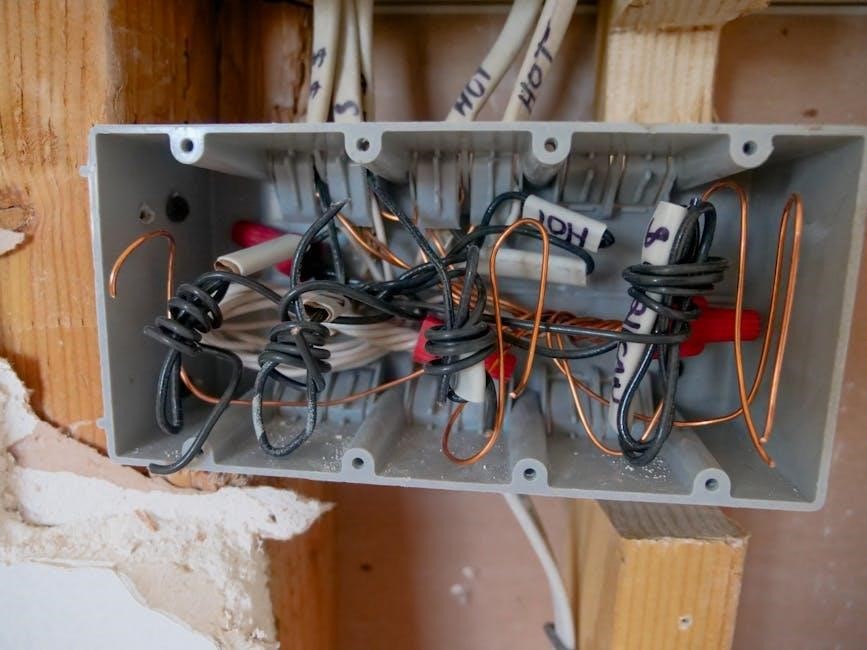

Wiring diagrams for 3-wire motors provide a clear visual guide for connecting the Franklin Electric control box to the motor and power supply. These diagrams outline the proper terminals for incoming power, motor leads, and control circuits. Ensure the yellow, blue, and other colored wires are connected according to the specified layout. The control box typically includes terminals for power input, motor output, and optional accessories like float switches or pressure sensors. Always refer to the Franklin Electric AIM manual for the exact wiring configuration, as incorrect connections can lead to system malfunctions or safety hazards. Properly following the wiring diagram ensures safe and efficient operation of the submersible motor system. This step is critical for maintaining motor performance and protecting the control box from potential damage. Adherence to the provided guidelines guarantees a reliable setup.

Connecting the Control Box to the Motor

Connecting the control box to the motor involves ensuring that all wires are securely attached to the correct terminals. Begin by identifying the motor leads and matching them to the control box terminals as specified in the Franklin Electric manual. The yellow and blue wires typically connect to the motor windings, while the black and red wires handle power supply and control circuits. Properly tightening the terminals is essential to maintain a safe and reliable connection. Additionally, ensure all grounding wires are securely attached to prevent electrical hazards. After connecting, verify that the overload reset button is functioning correctly to protect the system from overcurrent conditions. Finally, replace the control box cover and reconnect power, adhering to all safety precautions to avoid any potential risks. This ensures optimal performance and longevity of the motor and control system. Always follow the manufacturer’s guidelines for a secure and efficient setup.

Understanding Control Box Connections

Understanding the connections within a Franklin Electric control box is crucial for ensuring proper installation and operation. The control box features a terminal block that accepts conductors from AWG 20 to 6, providing secure wiring connections. The main overload reset button and start overload reset button are essential for protecting the motor from overcurrent conditions. The control box also includes knock-outs for 2″, 1.5″, and 0.75″ conduits, allowing for flexible wiring configurations. The left and right sides of the control box have designated knock-outs for easy access and installation. Properly understanding these connections ensures safe and efficient operation of the submersible motor system. Always refer to the Franklin Electric manual for specific wiring diagrams and connection guidelines to avoid any potential risks and ensure compliance with safety standards. This knowledge helps in troubleshooting and maintaining the system effectively, ensuring optimal performance and longevity.

Troubleshooting Common Issues

Troubleshooting Franklin Electric control boxes often involves addressing overload reset button tripping, capacitor issues, and wiring problems. Always check motor load, capacitor condition, and connections for faults before resetting or replacing components.

Overload Reset Button Tripping

The overload reset button on Franklin Electric control boxes may trip due to overcurrent conditions, such as motor overload, short circuits, or power surges. If the button trips frequently, it indicates a potential issue with the motor or wiring. To resolve this, first, ensure the motor is operating within its rated load. Check for any blockages or excessive demand on the motor. Verify that the control box is correctly sized for the motor’s horsepower and voltage. Inspect the wiring for loose connections or damage. Allow the motor and control box to cool down before pressing the reset button. If the issue persists, consult the Franklin Electric manual or contact a professional to diagnose and repair any underlying problems. Regular maintenance and inspections can help prevent recurring overload issues. Always prioritize safety when working with electrical systems.

Capacitor Testing and Replacement

Capacitor testing and replacement are crucial for maintaining the efficiency and reliability of Franklin Electric control boxes. To test the capacitor, use an ohmmeter set to the lowest setting. Disconnect power and discharge the capacitor before testing. Attach the ohmmeter leads to the capacitor terminals. A good capacitor will show a reading that drops and then rises toward infinity. If the reading remains low or high, the capacitor is faulty and needs replacement. When replacing, ensure the new capacitor matches the voltage and capacitance ratings specified in the manual. Properly dispose of the old capacitor. Regular testing and replacement prevent motor startup issues and ensure optimal performance. Always follow safety guidelines when handling electrical components to avoid hazards.

Adjusting Timeout Settings

Adjusting timeout settings on Franklin Electric control boxes ensures proper motor operation and protection. Timeout settings regulate how long the control box waits before resetting after an overload. To adjust, locate the timeout dial on the control box, typically marked with time intervals. Turn the dial to the desired setting, such as 2, 30, 60, or 120 minutes, based on the application. Ensure the setting aligns with the motor’s workload and operating conditions. Incorrect settings may lead to premature tripping or inadequate protection. After adjustment, reconnect power and test the system to confirm proper function. Always refer to the manual for specific instructions and recommendations. Proper timeout settings enhance system reliability and prevent unnecessary downtime.

Identifying Wiring Issues

Identifying wiring issues in Franklin Electric control boxes is crucial for ensuring reliable operation. Common problems include loose connections, incorrect wire sizing, or damaged insulation. Always start by disconnecting power and inspecting the wiring harness. Check for signs of wear, fraying, or corrosion. Verify that all connections to the terminal block are secure and match the wiring diagram provided in the manual. Pay particular attention to the yellow and blue wires, which are critical for proper motor operation. Use a multimeter to test for continuity and resistance. If a wire shows an open circuit or short, replace it immediately. Consult the manual for specific wiring configurations and troubleshooting steps. Addressing wiring issues promptly prevents motor damage and ensures safe, efficient system performance. Proper wiring is essential for the control box to function correctly and protect the motor from overloads or voltage fluctuations.

Specifications and Technical Details

Franklin Electric control boxes are rated for 220-230V, compatible with 1/3 to 15 HP motors, and feature IP-protected enclosures with capacitors and overload protection for reliable operation.

Horsepower and Voltage Ratings

Franklin Electric control boxes are designed to accommodate a wide range of motor sizes, typically supporting horsepower ratings from 1/3 HP to 15 HP. These control boxes are compatible with single-phase motors and operate at standard voltage levels of 220-230 volts, ensuring compatibility with most residential and light industrial electrical systems. The horsepower and voltage ratings are carefully matched to the motor specifications to ensure optimal performance and efficiency. Proper alignment of the control box ratings with the motor is critical to prevent overloading and ensure reliable operation. The control box is engineered to handle the startup and running currents of the motor, providing consistent power delivery and protection against voltage fluctuations. Always refer to the manual for specific horsepower and voltage ratings for your control box to ensure safe and efficient operation of your submersible motor system.

Enclosure Types and Protection Levels

Franklin Electric control boxes are available in various enclosure types to suit different environmental conditions. The standard enclosure is designed for indoor use, while more robust options, such as NEMA-rated enclosures, offer enhanced protection against dust, moisture, and other contaminants. These enclosures are built to withstand harsh conditions, ensuring reliable performance in both residential and industrial settings. Protection levels are defined by IP (Ingress Protection) ratings, with common ratings like IP 23 providing protection against solid particles and water splashing. The enclosures are typically made of durable materials, such as metal, to ensure long-lasting protection for internal components. Proper enclosure selection is crucial to maintain safety and efficiency, especially in outdoor or high-humidity applications. Always refer to the manual for specific enclosure ratings and recommendations for your operating environment.

Compatible Motor Types and Ratings

Franklin Electric control boxes are specifically designed to work with Franklin submersible motors, ensuring seamless compatibility and optimal performance. These control boxes support single-phase motors with power ratings from 1/3 to 15 horsepower, making them suitable for a wide range of applications, from residential water systems to industrial installations. The control boxes are engineered to handle the unique demands of submersible motors, providing precise control and protection. Motor voltage ratings typically range from 220 to 230 volts, ensuring compatibility with standard electrical systems. The control boxes are also designed to accommodate various motor speeds and torque requirements, ensuring efficient operation. Always check the manual to confirm the specific motor ratings and configurations supported by your control box to ensure proper functionality and safety.

Safety Precautions and Best Practices

Always handle electrical components with caution, ensure proper grounding, and use surge protectors to safeguard against voltage instability. Follow manual guidelines to prevent hazards and ensure safe operation.

Handling Electrical Components Safely

When working with Franklin Electric control boxes, always disconnect power before handling internal components. Use insulated tools to prevent shocks and ensure proper grounding to avoid electrical hazards. Never touch live circuits, and wear protective gear like gloves and safety glasses. Ensure the area is well-ventilated, and avoid overloading circuits. Follow the manual’s guidelines for safe operation and maintenance to prevent accidents. Proper handling ensures longevity and reliability of the control box and motor system, protecting both equipment and personnel from potential risks.

Importance of Proper Grounding

Proper grounding of Franklin Electric control boxes is essential to ensure safe operation and protect against electrical shocks. Grounding provides a safe path for stray currents to the earth, preventing potential hazards. A correctly grounded system ensures the control box operates within safe voltage levels and protects equipment from damage caused by power surges or spikes. Improper grounding can lead to malfunction, electrical fires, or injury. Always follow the manufacturer’s grounding instructions and verify the grounding system before installation. Ensure all connections are secure and free from corrosion. Proper grounding is critical for the reliability and safety of the entire motor system, making it a non-negotiable step in the setup process.

Surge Protection and Voltage Stability

Franklin Electric control boxes are designed to protect against voltage fluctuations and power surges, ensuring stable operation of submersible motors. Surge protection is crucial to prevent damage from sudden spikes in voltage, which can occur due to lightning strikes or grid instability. These control boxes often incorporate built-in surge protection devices or recommend external surge arresters to safeguard the system. Maintaining voltage stability ensures the motor operates within its rated specifications, preventing overheating and premature wear. Proper installation and regular maintenance of the control box are essential to uphold its protective capabilities. Additionally, using high-quality components and adhering to Franklin Electric’s guidelines helps ensure long-term reliability and safety of the motor system. Always prioritize surge protection and voltage stability to extend the lifespan and performance of your submersible motor setup.

Maintenance and Repair

Regular maintenance ensures optimal performance and longevity of Franklin Electric control boxes. Clean the enclosure, inspect connections, and replace worn or faulty components like capacitors. Schedule routine checks to prevent unexpected failures.

Cleaning and Inspecting the Control Box

Cleaning and inspecting the Franklin Electric control box is crucial for maintaining its functionality. Start by disconnecting the power supply to ensure safety. Use a soft, dry cloth to wipe down the exterior, removing any dirt or debris that may accumulate. For the interior, carefully vacuum or brush away dust from the components. Inspect all electrical connections and terminals for signs of wear, corrosion, or loose wires. Check the capacitors for any visible damage or swelling, as these are critical for motor startup. If you find any issues, address them promptly by tightening connections or replacing damaged parts. Regular cleaning prevents overheating and ensures reliable operation. Always refer to the manual for specific instructions and safety precautions during maintenance.

Checking and Replacing Capacitors

Capacitors in Franklin Electric control boxes play a vital role in motor startup and operation. To check them, disconnect power and discharge the capacitor using a resistor. Use an ohmmeter on the lowest setting to test for short circuits or opens. A good capacitor will show a rising resistance reading. If faulty, replace it with a Franklin Electric-approved capacitor of the same specifications. Ensure the new capacitor is properly seated and connections are secure. Improper replacement can cause motor failure or system malfunction. Always refer to the manual for specific capacitor ratings and replacement procedures. Regular checks help prevent unexpected downtime and ensure reliable motor performance. Proper handling and disposal of old capacitors are essential for safety and environmental compliance.

Resetting Overload Protectors

Overload protectors in Franklin Electric control boxes ensure motor safety by tripping during excessive current. To reset, switch off the control box and disconnect power. Allow the motor to cool if overloaded. Press and release the reset button; ensure it clicks. Reconnect power and test operation. If it trips again, check for wiring issues or motor overload. Regular reset verification prevents unexpected shutdowns and ensures system reliability. Always follow manual guidelines for safe and effective reset procedures.

Scheduling Regular Maintenance

Regular maintenance is crucial for ensuring the reliability and longevity of Franklin Electric control boxes. Schedule inspections every 6 to 12 months, depending on usage and environmental conditions. Check for dust, moisture, or corrosion that may affect performance. Clean the control box and its components using a soft brush or compressed air. Verify all connections are tight and secure. Test capacitors and overload protectors for proper function. Replace any worn or damaged parts immediately. For systems in harsh environments, consider more frequent maintenance. Keep a maintenance log to track inspections and repairs. Always refer to the Franklin Electric manual for specific guidelines and procedures. Regular maintenance prevents unexpected failures and ensures optimal system operation.

Calibration and Sensitivity Adjustment

Calibration ensures proper control box operation. Adjust timeout settings and sensitivity as needed. Test capacitors and relays for optimal performance. Refer to the manual for detailed procedures and factory settings.

Factory Calibration Settings

Franklin Electric control boxes come with predefined factory calibration settings to ensure optimal performance. These settings are configured to meet the specific requirements of the motor and system they control. The factory calibration ensures that the control box operates within the designed parameters, providing reliable protection and efficiency. Users should avoid altering these settings without proper guidance, as incorrect adjustments can lead to suboptimal performance or system malfunctions. If adjustments are necessary, refer to the Franklin Electric AIM Manual for detailed instructions. The manual provides step-by-step guidance on how to safely modify settings while maintaining system integrity. Always verify the settings with the appropriate tools and follow safety protocols to avoid electrical hazards. Proper calibration is essential for ensuring the longevity and efficiency of the motor and control system.

Adjusting Timeout and Sensitivity

Adjusting the timeout and sensitivity settings on a Franklin Electric control box is crucial for optimizing system performance. The timeout feature ensures the motor operates within safe parameters, preventing overheating or damage from prolonged operation. Sensitivity adjustments fine-tune the control box’s response to system conditions, such as pressure or flow changes. To adjust these settings, refer to the Franklin Electric AIM Manual, which provides detailed instructions. Typically, timeout settings can be modified using a potentiometer or digital interface, depending on the model. Sensitivity adjustments may involve tweaking relay settings or calibration parameters. Always use the correct tools and follow safety protocols when making adjustments. Improper settings can lead to system inefficiency or premature wear. After adjustments, test the system to ensure proper operation. Regular monitoring and adjustments are essential for maintaining optimal performance and protecting the motor and control components. Consult the manual for specific procedures and guidelines.

Testing the Potential Relay Coil

Testing the potential relay coil in a Franklin Electric control box ensures proper operation and reliability. Remove the relay from the control box to access the coil terminals. Using an ohmmeter, measure the resistance across the terminals. A good coil should show a specific resistance range, detailed in the Franklin AIM Manual. If the reading is inconsistent or open, the coil may be faulty. Additionally, check for voltage at the coil terminals while the system is operational. Proper voltage indicates the relay is functioning correctly. If voltage is absent, inspect wiring connections and ensure the control box is powered. Testing the relay coil regularly helps prevent unexpected system failures and ensures the motor operates efficiently. Always refer to the manual for specific test procedures and safety guidelines to avoid damage or injury. Regular testing maintains system integrity and extends component lifespan.

Franklin Electric control boxes are essential components for submersible motor systems, ensuring reliable operation and protection. Designed for 3-wire, single-phase motors, these control boxes offer advanced features like overload protection, capacitor testing, and adjustable settings. Proper installation, wiring, and maintenance are critical for optimal performance. Regular testing of components, such as the potential relay coil, and adherence to safety guidelines ensure system longevity. The Franklin AIM Manual provides comprehensive troubleshooting and technical details, making it a vital resource for users. By following the outlined procedures and best practices, users can maximize efficiency and prevent unexpected failures. Franklin Electric control boxes are a cornerstone of water and industrial systems, delivering durability and precision in demanding environments. Always prioritize safety and maintenance to ensure uninterrupted service from these high-quality control units.