owner manual 2003 ford expedition fuse box diagram

The 2003 Ford Expedition fuse box diagram is essential for understanding and maintaining your vehicle’s electrical systems. It outlines the locations and functions of fuses and relays‚ ensuring proper diagnostics and repairs. Referencing the owner’s manual or trusted resources provides accurate information for safe and effective fuse box operations.

1.1 Overview of the Fuse Box System

The 2003 Ford Expedition features a fuse box system designed to protect and control its electrical circuits. The system includes two main fuse boxes: one in the passenger compartment and another under the hood. Each fuse box houses multiple fuses and relays‚ ensuring power distribution to various vehicle components. Fuses act as circuit protectors‚ preventing overloads that could damage wiring or components. Relays‚ on the other hand‚ help control high-power devices like headlights and wipers. The fuse box system is organized to simplify troubleshooting‚ with each fuse assigned to specific functions. Always use the correct amperage-rated fuse to avoid electrical damage or fire hazards. Consulting the owner’s manual or a trusted diagram is crucial for accurate fuse identification and safe repairs.

1.2 Importance of the Fuse Box Diagram

The fuse box diagram is crucial for identifying and troubleshooting electrical issues in the 2003 Ford Expedition. It provides a clear visual representation of fuse locations‚ their ratings‚ and the circuits they control. This diagram helps owners and technicians quickly pinpoint blown fuses‚ understand circuit functions‚ and perform safe repairs. By ensuring the correct fuse is used‚ it prevents potential damage or fire risks. The diagram also simplifies diagnostics‚ saving time and reducing the likelihood of incorrect fuse replacements. Regularly referencing the fuse box diagram helps maintain vehicle reliability and ensures all electrical components function as intended. Always consult the owner’s manual or a trusted source for the most accurate and up-to-date information.

Location of the Fuse Box in the 2003 Ford Expedition

The 2003 Ford Expedition has two main fuse boxes. The passenger compartment fuse box is located on the driver’s side dashboard‚ behind a cover. The under-hood fuse box is found on the driver’s side‚ under the hood‚ near the engine compartment.

2.1 Passenger Compartment Fuse Box

The passenger compartment fuse box in the 2003 Ford Expedition is situated on the driver’s side dashboard‚ behind a protective cover. This fuse box controls various interior and convenience features such as climate control‚ radio‚ power windows‚ and lighting systems. It also manages functions like the moonroof‚ DVD player‚ and navigation systems. The fuses are color-coded and labeled for easy identification‚ ensuring that drivers can quickly locate and replace blown fuses. The owner’s manual provides a detailed diagram of the passenger compartment fuse box‚ outlining the specific functions of each fuse and relay. This makes troubleshooting and maintenance straightforward for vehicle owners. Always refer to the manual for accurate information to avoid electrical system damage;

2.2 Under-Hood Fuse Box

The under-hood fuse box in the 2003 Ford Expedition is located on the driver’s side of the engine compartment. It houses fuses and relays that control essential vehicle systems such as the powertrain control module (PCM)‚ fuel pump‚ and cooling fan. This fuse box also manages components like the anti-lock braking system (ABS)‚ air suspension‚ and 4×4 module. The fuses are organized by function‚ with labels provided on the fuse box cover or in the owner’s manual. It’s important to disconnect the battery before working on this fuse box to ensure safety. Always consult the manual for accurate fuse identification and replacement procedures to avoid damaging the electrical system. Proper maintenance of this fuse box is crucial for reliable vehicle operation;

Fuse Box Layout and Diagram Explanation

The fuse box layout for the 2003 Ford Expedition is organized by system‚ with fuses and relays clearly labeled for easy identification and troubleshooting. Referencing the owner’s manual or a detailed diagram ensures accurate fuse location and function understanding‚ helping to simplify repairs and maintenance. This systematic approach allows drivers to quickly diagnose and address electrical issues‚ ensuring optimal vehicle performance and safety. Always cross-check the diagram with the manual for precise information.

3.1 Passenger Compartment Fuse Box Diagram

The passenger compartment fuse box in the 2003 Ford Expedition is located on the right side of the instrument panel‚ behind a trim panel. This fuse box controls essential interior features such as power windows‚ radio‚ climate control‚ and interior lighting. The diagram provided in the owner’s manual or online resources lists each fuse by number and its corresponding system. Fuses like F1.4 for the DVD player and F22 for power windows are highlighted‚ ensuring easy identification. Referencing this diagram helps drivers quickly locate and replace blown fuses‚ minimizing downtime and ensuring all interior components function properly. Always use the correct fuse rating to maintain electrical system integrity.

3.2 Under-Hood Fuse Box Diagram

The under-hood fuse box in the 2003 Ford Expedition is located on the driver’s side of the engine compartment. This fuse box primarily handles high-current systems such as the powertrain‚ cooling fans‚ and anti-lock braking system (ABS). The diagram highlights fuses like F1.15 for the fuel pump and F1.16 for the ABS module. Relays for components like the electronic cooling fan and speed control servo are also detailed. Consulting the owner’s manual or a reliable resource ensures accurate identification of each fuse and relay‚ aiding in efficient troubleshooting and maintenance. Remember to always use the correct amperage-rated fuses to avoid electrical system damage.

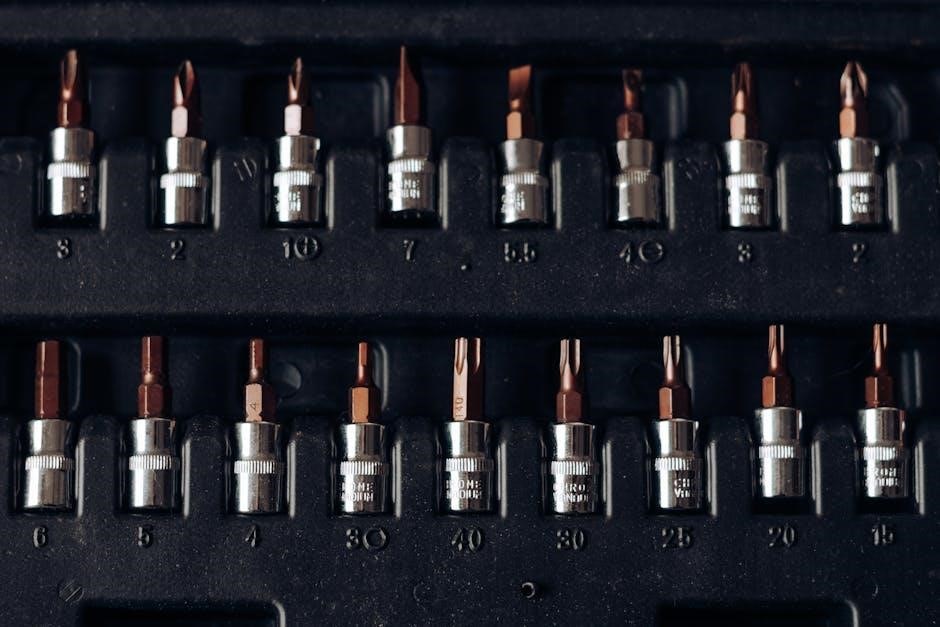

Components and Their Corresponding Fuses

The 2003 Ford Expedition’s fuse box links components like the moonroof‚ power windows‚ and radio to specific fuses‚ such as F1.4 for the DVD player and F1.15 for the fuel pump.

4.1 Interior Components (e.g.‚ Climate Control‚ Radio‚ Lights)

The interior components of the 2003 Ford Expedition are managed by specific fuses in the passenger compartment fuse box. The climate control system‚ including the A/C compressor and blower motor‚ is powered by fuses such as F1.14 and F1.15. The radio and entertainment systems‚ including the CD player and rear seat audio controls‚ are supported by fuse F1.4. Interior lighting‚ such as the dome‚ glove compartment‚ and cargo area lamps‚ are controlled by fuses F1.10 and F1.9. Additionally‚ the moonroof switch and power windows operate through fuses like F1.20 and F1.25‚ ensuring all interior features function properly.

4.2 Exterior Components (e.g.‚ Headlights‚ Wipers‚ Mirrors)

The exterior components of the 2003 Ford Expedition are powered by specific fuses located in both the passenger compartment and under-hood fuse boxes. The headlights‚ including low and high beam functions‚ are supported by fuses such as F1.29 (parklamps) and F1.31 (front wiper motor and washer pump). The rear wiper motor and washer pump are controlled by fuse F1.30. Heated mirrors are managed by fuse F1.8‚ while the power mirrors and memory seat functions are supported by fuse F1.7. These fuses ensure proper operation of exterior features‚ maintaining safety and convenience while driving.

4.3 Convenience Features (e.g.‚ Power Windows‚ Moonroof‚ DVD Player)

The 2003 Ford Expedition’s convenience features are managed through specific fuses in the passenger compartment and under-hood fuse boxes. Power windows‚ including the moonroof‚ are controlled by fuse F2.27 (delayed accessory relay)‚ ensuring proper operation of all glass functions. The DVD player is powered by fuse F1.4‚ which also supports rear seat audio controls and the CD player. These fuses are essential for maintaining entertainment and comfort systems. Always refer to the owner’s manual or a reliable fuse box diagram for accurate fuse locations and ratings to avoid electrical issues or damage to components.

Safety Precautions When Working with Fuses

Always turn off the ignition and ensure the vehicle is stationary before handling fuses. Replace fuses with the correct amperage rating to prevent damage or fire hazards.

5.1 Electrical Safety Tips

When working with the 2003 Ford Expedition’s fuse box‚ always disconnect the battery to avoid electric shocks or short circuits. Use protective gloves and eyewear. Never touch electrical components with wet hands. Ensure the ignition is off and all accessories are powered down. Avoid using damaged tools or fuses‚ as they can cause further issues. If a fuse blows repeatedly‚ consult a professional. Always refer to the owner’s manual for specific guidelines tailored to your vehicle. Proper adherence to these safety measures ensures a safe and effective fuse replacement process‚ preventing potential hazards and maintaining your vehicle’s electrical integrity.

5.2 Best Practices for Replacing Fuses

When replacing fuses in your 2003 Ford Expedition‚ always consult the owner’s manual to identify the correct fuse and its location. Use a fuse puller to avoid bending or damaging the fuse or holder. Ensure the replacement fuse matches the specified amperage rating to prevent electrical damage or fire hazards. Turn off the engine‚ lights‚ and all accessories before replacing a fuse. Test the affected system after installation to confirm functionality. Avoid using makeshift or higher-rated fuses‚ as they can cause severe electrical issues. If a fuse blows repeatedly‚ inspect the circuit for underlying problems. Always keep spare fuses of the correct type in your vehicle for emergencies. Follow these steps to maintain your vehicle’s electrical system safely and efficiently.

Troubleshooting Common Fuse-Related Issues

Troubleshooting fuse-related issues in the 2003 Ford Expedition involves identifying blown fuses‚ testing circuits‚ and replacing faulty components. Consult the owner’s manual for guidance and use proper tools to ensure safe and effective diagnostics. If a fuse blows repeatedly‚ inspect the related circuit for short circuits or malfunctioning parts. Always replace fuses with the correct amperage rating to prevent further damage. Regular inspections and maintenance can help prevent electrical system failures. Refer to the fuse box diagram for accurate fuse locations and functions to streamline the troubleshooting process.

6.1 Identifying Blown Fuses

Identifying blown fuses in the 2003 Ford Expedition requires a systematic approach. Start by locating the fuse box‚ either in the passenger compartment or under the hood‚ as specified in the owner’s manual. Open the fuse box and inspect each fuse visually for signs of damage‚ such as a broken or burnt filament. Use a fuse puller to remove each fuse and check its condition. A blown fuse will have a broken or darkened filament. Additionally‚ use a multimeter to test for continuity; a blown fuse will show an open circuit. Replace any faulty fuses with ones of the exact same amperage rating to ensure proper function and safety. Always refer to the fuse box diagram in the owner’s manual to identify the correct fuse for each component. This method ensures accurate diagnostics and prevents further electrical issues.

6.2 Resetting or Replacing Fuses

Resetting or replacing fuses in the 2003 Ford Expedition is a straightforward process when done correctly. Always disconnect the power source by turning off the ignition and all electrical components. Locate the fuse box‚ either in the passenger compartment or under the hood‚ using the diagram from the owner’s manual. Use a fuse puller to remove the suspected blown fuse. Inspect it visually for a broken filament or dark coloration. Replace it with a fuse of the exact same amperage rating to ensure proper function. For resettable fuses‚ simply wait a few minutes and reinsert them. If a fuse blows again‚ consult the manual or a professional to address the underlying issue. Always prioritize safety and refer to the owner’s manual for guidance.

Owner Manual References for Fuse Box Operations

Consult the owner’s manual for detailed fuse box diagrams and operation instructions specific to the 2003 Ford Expedition. It provides essential guidance for safe troubleshooting and repairs.

7.1 Navigating the Owner Manual for Fuse Box Information

To locate fuse box details in the 2003 Ford Expedition owner manual‚ start by checking the table of contents or index for “Fuse Box Diagram” or “Electrical Systems.” The manual typically includes a dedicated section with diagrams and explanations of fuse locations‚ functions‚ and related components. Look for illustrations that highlight both the passenger compartment and under-hood fuse boxes. Refer to the numbered or labeled fuses to identify which ones control specific features like lights‚ climate control‚ or power outlets. The manual may also provide troubleshooting tips and safety guidelines for handling fuses. Always cross-reference the information with your vehicle’s specific model year to ensure accuracy.

7.2 Additional Resources for Fuse Box Diagrams

Beyond the owner’s manual‚ additional resources like online forums‚ automotive websites‚ and repair guides provide detailed fuse box diagrams for the 2003 Ford Expedition. Websites such as startmycar.com and fusecheck.com offer comprehensive diagrams and troubleshooting tips. YouTube tutorials and repair forums also share hands-on experiences and visual guides. These resources are particularly useful for identifying specific fuses related to components like the DVD player‚ power windows‚ or climate control. Always ensure the resource matches your vehicle’s model year to avoid confusion. Using these tools can enhance your understanding and simplify fuse-related repairs.

Fuse Box Variations Across Model Years

Fuse boxes vary across model years‚ with differences in layout and fuse assignments. Always use the correct diagram for your specific year to ensure accuracy and safety.

8.1 Differences Between 2003 and Later Models

The 2003 Ford Expedition fuse box differs from later models‚ particularly in fuse assignments and relay locations. Starting from 2004‚ additional fuses were introduced for new features like advanced climate control and electronic stability systems. The 2003 model focuses on basic functionalities‚ with fuses allocated to essential systems such as lighting‚ wipers‚ and power outlets. In contrast‚ later models incorporate more complex components‚ leading to a more detailed fuse box layout. These variations emphasize the importance of using model-specific diagrams for accurate troubleshooting and maintenance‚ ensuring that repairs are done safely and effectively without causing further electrical issues.

8.2 Importance of Using the Correct Fuse Box Diagram

Using the correct fuse box diagram for your 2003 Ford Expedition is crucial for proper electrical system maintenance. Incorrect diagrams can lead to misidentification of fuses‚ potentially causing damage to components or safety risks. The correct diagram ensures accurate troubleshooting‚ helping to identify blown fuses quickly and replace them with the right amperage rating. This prevents overloading circuits and reduces the risk of electrical fires. Additionally‚ it helps maintain the vehicle’s reliability and performance‚ ensuring all systems function as intended. Always refer to model-specific resources or the owner’s manual for precise information tailored to your vehicle’s configuration.

Interactive Fuse Box Diagrams and Tools

Interactive fuse box diagrams provide detailed‚ clickable visuals for the 2003 Ford Expedition‚ allowing users to identify fuses and relays quickly. These tools enhance troubleshooting efficiency and accuracy.

9.1 Online Resources for Interactive Fuse Box Diagrams

Several websites offer interactive fuse box diagrams for the 2003 Ford Expedition‚ providing detailed visuals and clickable elements. These resources allow users to quickly identify fuses and relays‚ streamlining diagnostics. Websites like startmycar.com and fusecheck.com provide comprehensive diagrams‚ while others offer searchable databases. These tools are invaluable for troubleshooting electrical issues‚ ensuring accurate repairs. By utilizing these resources‚ owners can efficiently locate and address blown fuses or faulty relays‚ saving time and effort. Always refer to trusted sources to ensure the diagrams match your vehicle’s specifications for reliable maintenance and repairs.

9.2 Using Software for Fuse Box Troubleshooting

Specialized software tools can enhance fuse box troubleshooting for the 2003 Ford Expedition. Programs like FORScan or AutoEnginuity provide real-time diagnostics‚ helping pinpoint electrical issues. These tools often include detailed fuse box layouts and allow users to monitor system performance. By connecting to the vehicle’s PCM‚ they can identify faults and guide repairs. Some software also offers step-by-step troubleshooting‚ reducing guesswork. Compatibility with OBD-II scanners ensures accurate data retrieval. These resources are particularly useful for diagnosing complex issues‚ such as intermittent faults or multiple blown fuses. Regular updates ensure the software stays current with vehicle specifications‚ making it a reliable solution for DIY enthusiasts and professionals alike.

Common Fuse-Related Issues and Solutions

Common issues include blown fuses for power windows‚ rear wipers‚ and climate control. Solutions involve replacing fuses with correct amperage ratings and addressing electrical shorts or corrosion.

10.1 Frequently Blown Fuses and Their Causes

Fuse 22 is a common culprit‚ often blowing due to issues with power windows or moonroof components. Overloaded circuits from faulty switches or electrical shorts can cause repeated failures. Similarly‚ Fuse 35‚ responsible for high-beam headlamps‚ may blow from damaged bulbs or wiring issues. The Rear Window Defroster fuse (Fuse 8) can fail due to heating element damage or excessive use. Additionally‚ the DVD player fuse (F1.4) may blow if the system malfunctions or has power surges. Addressing these issues promptly by replacing fuses with correct ratings and repairing underlying causes ensures reliable electrical system performance. Always consult the owner’s manual or a professional for complex repairs.

10;2 DIY Fixes for Minor Fuse Box Problems

For minor fuse box issues‚ start by identifying blown fuses using the diagram in your owner’s manual. Replace fuses with ones of the exact amperage rating to avoid damage. Ensure the ignition is off and all accessories are disconnected before handling fuses. Use a fuse puller for safe removal and avoid touching electrical components. If a fuse blows repeatedly‚ inspect the circuit for shorts or overload. Clean corroded connections and verify switch functionality. For non-essential systems like the radio or moonroof‚ temporary disconnection can help isolate issues. Always refer to online resources or Ford’s official guides for specific instructions. Regular maintenance can prevent many common fuse-related problems.