tefal air fryer manual pdf

Finding the correct Tefal Air Fryer manual‚ often in PDF format‚ is crucial for optimal use and safety of your appliance․ These guides offer verified setup instructions․

Importance of the Manual

Your Tefal Air Fryer manual‚ readily available as a PDF download‚ is far more than just a set of instructions; it’s your key to unlocking the full potential of this versatile kitchen appliance․ It provides essential guidance on safe operation‚ ensuring you avoid potential hazards and maximize the lifespan of your fryer․

Understanding the specific features of your model‚ from the control panel to pre-set programs‚ is detailed within the manual․ Troubleshooting common issues‚ like uneven cooking or heating problems‚ becomes significantly easier with the provided solutions․ Accessing this information empowers you to confidently prepare a wide variety of meals‚ guaranteeing delicious results every time․

Where to Find Official Tefal Air Fryer PDFs

Locating official Tefal Air Fryer manuals in PDF format is straightforward․ Begin by exploring the Tefal website’s support section‚ often featuring a dedicated manuals library․ Numerous online resources specialize in hosting appliance manuals‚ ensuring you find the correct owner’s guide for your specific model․

These catalogs focus on securing hard-to-find documents‚ providing verified setup guides and troubleshooting instructions․ Websites offering FAQs and product support frequently link directly to downloadable PDF manuals․ Remember to search using your precise model number (e․g․‚ EY1208) for accurate results‚ guaranteeing you have the correct information․

Understanding Your Tefal Air Fryer Model

Identifying your specific Tefal Air Fryer model number is essential before consulting the manual‚ ensuring you access the correct instructions and safety guidelines․

Identifying Your Specific Model Number

Locating your Tefal Air Fryer’s model number is the first step towards accessing the correct manual‚ often available as a PDF download․ This unique identifier ensures you receive instructions tailored specifically to your appliance․ The model number is typically found on a sticker located on the underside or rear of the unit․

It may also be present on the original packaging or in the documentation that came with your Air Fryer․ Having this number readily available streamlines the process of finding the appropriate manual online‚ guaranteeing accurate guidance for setup‚ operation‚ and troubleshooting․ Without it‚ you risk using instructions intended for a different model․

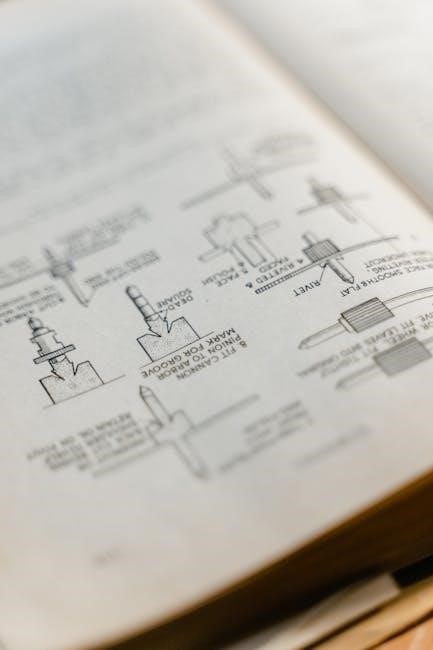

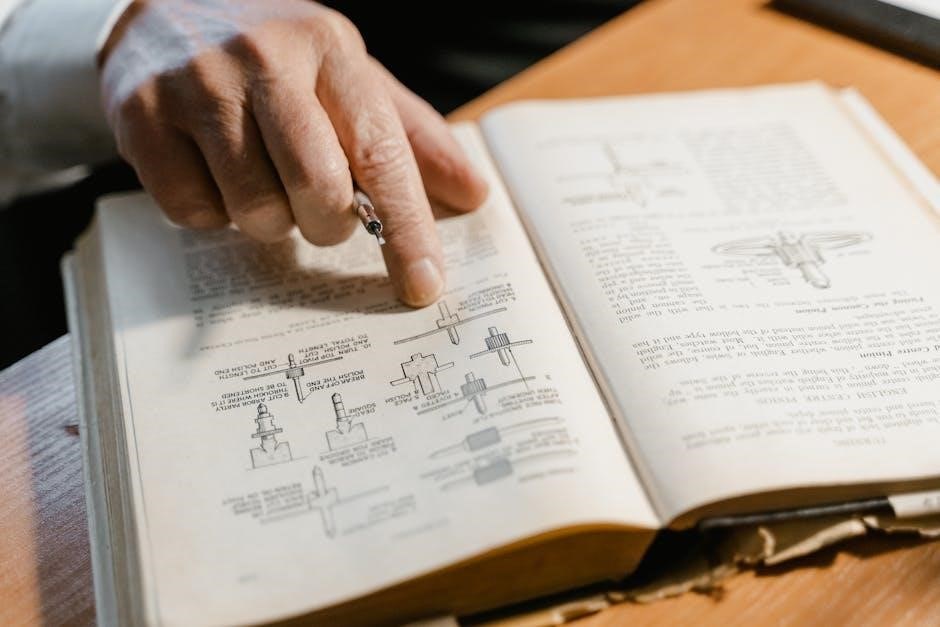

Key Components and Their Functions

Understanding the core components of your Tefal Air Fryer‚ as detailed in the manual (often a PDF)‚ is essential for safe and effective operation․ Key parts include the cooking basket‚ responsible for holding food during the air frying process‚ and the control panel‚ used to adjust settings․

The heating element circulates hot air‚ while the timer and temperature controls allow for precise cooking․ Familiarizing yourself with each component’s function‚ as outlined in your specific model’s manual‚ ensures optimal performance and longevity of your appliance․ Refer to the PDF for detailed diagrams and explanations․

Safety Precautions Before First Use

Before operating your Tefal Air Fryer‚ carefully review the safety precautions detailed in the user manual – frequently available as a PDF download․ Ensure the appliance is placed on a stable‚ heat-resistant surface‚ away from flammable materials․

Always inspect the power cord for damage and never immerse the appliance in water․ Remove all packaging materials and labels before initial use․ The manual’s safety section provides critical guidance to prevent hazards and ensure safe operation․ Adhering to these guidelines‚ found within the PDF‚ is paramount for user safety․

Setting Up Your Tefal Air Fryer

Consult your Tefal Air Fryer manual (often a PDF) for detailed setup instructions‚ including initial cleaning and understanding the control panel’s functions․

Initial Cleaning and Preparation

Before your first use‚ thoroughly clean your Tefal Air Fryer‚ referencing the detailed instructions within your appliance’s manual – frequently available as a PDF download․ This ensures removal of any manufacturing residues․ Wash the basket and pan with warm‚ soapy water; these parts are often dishwasher safe‚ but always confirm this in the manual․ Wipe the interior and exterior with a damp cloth․

Proper preparation extends the lifespan of your Air Fryer and guarantees optimal cooking performance․ The manual will also detail any specific preparation steps unique to your model‚ such as a brief initial heating cycle to eliminate any lingering odors․

Control Panel Overview & Digital Display

The Tefal Air Fryer’s control panel‚ detailed in your manual (often a downloadable PDF)‚ features intuitive buttons or a touchscreen for selecting pre-set programs‚ adjusting temperature‚ and setting the timer․ The digital display clearly shows the cooking time and temperature‚ providing real-time feedback during operation․

Familiarize yourself with each button’s function – power‚ temperature control‚ timer adjustment‚ and program selection – as outlined in the manual․ Understanding the display’s indicators‚ such as preheating or cooking progress‚ will enhance your cooking experience and ensure precise results․

Temperature and Timer Settings Explained

Your Tefal Air Fryer manual (available as a PDF download) provides detailed guidance on temperature and timer settings․ Temperatures typically range from 80°C to 200°C‚ influencing cooking speed and crispness․ The timer allows precise control‚ usually up to 60 minutes‚ ensuring perfectly cooked results․

Refer to the manual’s cooking guide for recommended settings for various foods․ Adjusting temperature and time based on quantity and desired doneness is key․ Understanding these settings‚ as detailed in the PDF‚ unlocks the full potential of your Air Fryer․

Cooking with Your Tefal Air Fryer

Consult your Tefal Air Fryer manual (PDF) for recommended cooking times and temperatures for diverse foods‚ ensuring delicious and perfectly prepared meals․

Recommended Cooking Times for Common Foods

Your Tefal Air Fryer manual‚ readily available as a PDF download‚ provides a detailed cooking guide for numerous dishes․ For chicken breast‚ expect approximately 20-40 minutes at 180°C (356°F)‚ while frozen chicken wings (around 220g/6 pieces) typically require 16-25 minutes at 200°C (392°F)․

However‚ these are merely estimations; always refer to the specific cooking chart within your model’s manual․ Factors like food thickness and initial temperature influence cooking duration․ The manual also offers guidance on preparing fries‚ vegetables‚ and other popular items‚ ensuring consistently excellent results․ Precise instructions are key to maximizing your Air Fryer’s potential․

Cooking Chicken Recipes (Breast‚ Wings)

The Tefal Air Fryer manual‚ often found as a convenient PDF‚ details optimal chicken cooking parameters․ For succulent chicken breasts‚ the manual suggests 20-40 minutes at 180°C (356°F)․ Frozen chicken wings (a 220g/6-piece portion) generally require 16-25 minutes at 200°C (392°F) for a crispy finish․

However‚ the manual emphasizes that these times are guidelines․ Adjustments may be needed based on wing size or breast thickness․ Always consult the dedicated Cooking Guide within your manual for precise instructions tailored to your specific Tefal model‚ ensuring perfectly cooked chicken every time․

Cooking Frozen Foods – Best Practices

Your Tefal Air Fryer manual‚ readily available as a PDF download‚ provides essential guidance for cooking frozen foods․ It generally recommends no pre-thawing for items like fries‚ nuggets‚ or vegetables‚ maximizing convenience․ However‚ the manual stresses the importance of shaking the basket midway through cooking to ensure even crisping․

Refer to the manual’s cooking guide for specific times and temperatures‚ as these vary significantly depending on the food type and quantity․ Overcrowding the basket can lead to uneven cooking; work in batches for optimal results․ The manual also advises checking for doneness before serving․

Troubleshooting Common Issues

The Tefal Air Fryer manual PDF details error codes and solutions; it assists with issues like heating problems or uneven cooking‚ ensuring optimal performance․

Air Fryer Not Heating Up

If your Tefal Air Fryer isn’t heating‚ consult the manual PDF for specific troubleshooting steps․ The document outlines potential causes‚ such as a faulty power connection or a heating element malfunction․ Always ensure the appliance is correctly plugged in and the power outlet is functioning․

Refer to the manual for guidance on resetting the device or checking for any error codes displayed on the digital panel․ It may also advise inspecting the internal components‚ but only if you are comfortable and qualified to do so․ Ignoring safety precautions could lead to damage or injury; therefore‚ professional assistance is recommended for complex issues․

Error Codes and Their Meanings

Your Tefal Air Fryer’s manual PDF contains a dedicated section detailing error codes and their corresponding meanings․ These codes signal specific issues‚ ranging from sensor malfunctions to overheating problems․ Understanding these codes is vital for efficient troubleshooting and preventing further damage․

The manual provides clear explanations for each code‚ guiding you through potential solutions․ It may suggest simple fixes like restarting the appliance or contacting customer support for more complex errors․ Always refer to the manual before attempting any repairs‚ ensuring you follow safety guidelines and avoid voiding your warranty․

Food Not Cooking Evenly

If your Tefal Air Fryer isn’t cooking food evenly‚ consult the manual’s troubleshooting section within the PDF․ Uneven cooking often stems from overcrowding the basket; the manual emphasizes the importance of proper food arrangement for optimal air circulation․

Additionally‚ the manual advises shaking or flipping food midway through the cooking process․ This ensures all sides are exposed to the hot air․ Check the manual for recommended basket capacity and food placement guidelines specific to your model‚ maximizing even cooking results and preventing burnt or undercooked portions․

Advanced Features & Functions

The Tefal Air Fryer manual (PDF) details pre-set programs‚ grill/roast/bake functions‚ and maximizing space in extra-large capacity models for versatile cooking․

Pre-set Cooking Programs

Tefal Air Fryer manuals (PDF versions readily available online) extensively cover the pre-set cooking programs designed for convenience and optimal results․ These programs automate cooking parameters for popular dishes like fries‚ chicken‚ fish‚ and even desserts‚ eliminating guesswork․ The manual details each program’s default time and temperature settings‚ allowing for easy operation․

Users can find specific instructions on utilizing these programs within their model’s manual‚ often including suggested food weights for best outcomes․ Furthermore‚ the manual explains how to slightly adjust these pre-sets to personalize cooking to individual preferences‚ ensuring perfectly cooked meals every time․ Understanding these programs unlocks the full potential of your Tefal Air Fryer․

Using the Grill/Roast/Bake Functions

Tefal Air Fryer manuals‚ accessible as PDF downloads‚ provide detailed guidance on utilizing the versatile Grill‚ Roast‚ and Bake functions․ These functions expand cooking possibilities beyond simple frying‚ allowing for diverse meal preparation․ The manual clarifies temperature and time recommendations for each function‚ ensuring optimal results for various foods․

It explains how to achieve a grilled effect‚ perfectly roasted meats‚ and evenly baked goods․ Users will find specific instructions on preheating‚ food placement‚ and potential adjustments needed based on their Air Fryer model․ Referencing the manual unlocks the full potential of these features‚ delivering restaurant-quality meals at home․

Extra-Large Capacity Models – Maximizing Space

Tefal Air Fryer manuals‚ often available as a PDF‚ detail strategies for maximizing the space within extra-large capacity models like the Easy Fry XL․ These guides emphasize proper food arrangement to ensure even cooking‚ preventing overcrowding which can lead to uneven results․ The manual illustrates optimal basket loading techniques‚ suggesting layering or single-layer placement depending on the food type․

It also explains how to utilize multiple racks or accessories effectively․ Understanding these guidelines‚ found within your model’s manual‚ allows you to efficiently cook larger portions‚ perfect for families or meal prepping‚ while maintaining consistent quality and crispness․

Cleaning and Maintenance

Tefal Air Fryer manuals (PDF format) provide detailed cleaning procedures‚ including daily routines and deep cleaning steps‚ plus dishwasher-safe part identification․

Daily Cleaning Procedures

Tefal Air Fryer manuals‚ readily available as PDF downloads‚ emphasize consistent daily cleaning for optimal performance and longevity․ After each use‚ disconnect the appliance and allow it to cool completely․ Remove the basket and pan; these are typically non-stick and can be washed with warm‚ soapy water․

The manual instructs to avoid abrasive cleaners that could damage the non-stick coating․ Wipe the interior and exterior of the Air Fryer with a damp cloth․ Ensure all parts are thoroughly dried before reassembly․ Regular adherence to these simple steps‚ detailed in your PDF manual‚ prevents food buildup and maintains hygiene․

Deep Cleaning Your Air Fryer

Your Tefal Air Fryer manual‚ accessible as a PDF‚ recommends periodic deep cleaning to maintain peak performance․ Disconnect and cool the appliance completely․ Remove all removable parts – basket‚ pan‚ and any accessories – and wash them thoroughly with warm‚ soapy water․ For stubborn residue‚ a paste of baking soda and water can be effective‚ as detailed in some manuals․

Wipe down the interior‚ paying attention to the heating element (avoid direct water contact!)․ The PDF manual may advise occasional cleaning of the exterior with a damp cloth․ Ensure all components are completely dry before reassembling‚ preventing potential issues;

Dishwasher Safe Parts

Consult your Tefal Air Fryer manual – often available as a PDF download – to confirm which components are dishwasher safe․ Typically‚ the basket and pan are designed for dishwasher cleaning‚ offering convenience․ However‚ the manual may specify a gentle cycle and avoiding harsh detergents to preserve the non-stick coating․

The housing unit and electrical components should never be placed in the dishwasher․ Always check the PDF manual for specific instructions related to your model․ Handwashing these parts is recommended to ensure longevity and prevent damage‚ maintaining optimal functionality․

Tefal Air Fryer Manual Resources

Tefal provides online FAQs and PDF manuals for various models‚ like the EY1208‚ ensuring easy access to instructions and troubleshooting guidance․

Accessing Online FAQs

Tefal’s website offers a comprehensive collection of frequently asked questions (FAQs) designed to quickly address common user inquiries regarding their Air Fryer models․ These online resources are readily available and provide instant solutions to many operational or troubleshooting concerns‚ potentially eliminating the need to download a full manual․

The FAQs cover a wide range of topics‚ from initial setup and cleaning procedures to specific cooking questions and error code explanations․ Users can easily navigate the FAQ section by browsing categories or utilizing the search function to pinpoint relevant information․ Accessing these resources is a convenient way to resolve issues and maximize the functionality of your Tefal Air Fryer‚ often available in PDF format for easy viewing․

Downloading Specific Model Manuals (EY1208 Example)

Tefal provides direct access to PDF versions of their Air Fryer manuals on their official website․ To locate the manual for a specific model‚ such as the Easy Fry Air Fryer EY1208‚ users can utilize the search function or navigate through the product catalog․ This ensures you obtain the correct documentation tailored to your appliance’s features and functions․

The manual typically includes detailed instructions on operation‚ safety precautions‚ cooking guidelines‚ and troubleshooting tips․ Downloading the PDF allows for offline access and easy printing․ These resources are essential for understanding your Air Fryer and ensuring optimal performance‚ offering a convenient alternative to physical copies․

Cooklite Aero Fryer Instructions

Cooklite Aero Fryer instructions‚ often available as a PDF download‚ detail the operation of this specific Tefal Air Fryer model․ These guides cover essential aspects like initial setup‚ control panel functions‚ recommended cooking times‚ and cleaning procedures․ Accessing the PDF ensures users have a readily available resource for maximizing their cooking experience․

The manual provides insights into utilizing the Aero Fryer’s unique features and achieving optimal results with various recipes․ It’s crucial for understanding safety guidelines and troubleshooting common issues․ Finding this PDF online simplifies appliance usage and extends its lifespan‚ offering a convenient solution for all users․

Warranty Information & Support

Tefal provides warranty coverage for its Air Fryers; support and manuals (including PDF versions) are accessible through their official customer service channels online․

Tefal Warranty Coverage

Tefal stands behind the quality of its Air Fryers‚ offering a standard warranty to protect against manufacturing defects․ The duration of this warranty can vary depending on the specific model and the country of purchase‚ so reviewing your product’s documentation – often available as a PDF manual – is essential․

Typically‚ the warranty covers issues arising from normal household use‚ but it doesn’t extend to damage caused by misuse‚ accidents‚ or unauthorized repairs․ Retaining proof of purchase is vital for any warranty claim․ Detailed warranty terms and conditions are usually outlined within the Air Fryer’s official manual‚ readily accessible online as a downloadable PDF․

Contacting Tefal Customer Support

Tefal provides multiple avenues for customers needing assistance with their Air Fryers‚ even if you’ve misplaced the physical manual․ Their website offers a comprehensive FAQ section‚ often addressing common queries and troubleshooting steps․ You can also typically find a downloadable PDF version of your specific model’s manual online․

For more personalized support‚ Tefal offers phone and email contact options․ Details for reaching their customer service team are usually listed on their official website‚ alongside helpful resources like instructional videos․ Having your Air Fryer’s model number handy – found within the manual or on the appliance itself – will expedite the support process․