ductwork installation guide pdf

Ductwork Installation Guide: A Comprehensive Plan

This comprehensive guide details ductwork installation, referencing SMACNA manuals and BSRIA guides for optimal HVAC system performance. UL 181 standards and CLIMAVER installation are covered.

Understanding Ductwork Systems

Ductwork systems are the circulatory network of any HVAC (Heating, Ventilation, and Air Conditioning) system, responsible for distributing conditioned air throughout a building. A properly designed and installed duct system ensures efficient heating and cooling, contributing significantly to indoor comfort and energy savings.

These systems typically consist of a network of interconnected ducts, originating from the central HVAC unit. Main trunk lines carry large volumes of air, branching into smaller ducts that deliver airflow to individual rooms or zones. Understanding the principles of static regain, as outlined in SMACNA’s HVAC Systems—Duct Design manual, is crucial for maintaining consistent airflow and minimizing energy loss.

Effective ductwork isn’t simply about pipes; it’s about airflow dynamics. Air diffusion supply duct systems offer alternatives to traditional methods, improving performance. Proper installation, adhering to standards like UL 181, is paramount. Resources like BSRIA guides help clarify complexities, particularly with flexible ductwork, ensuring optimal building performance and avoiding common pitfalls during installation.

Types of Ductwork Materials

Several materials are commonly used in ductwork installation, each with distinct advantages and disadvantages. Sheet metal, traditionally galvanized steel or aluminum, offers durability and rigidity, making it suitable for main trunk lines. However, it requires skilled fabrication and can be prone to noise transmission.

Flexible ductwork, often constructed from a wire helix encased in a plastic film, provides ease of installation, particularly in tight spaces. BSRIA guides address concerns surrounding flexible ductwork, emphasizing proper support and minimizing bends to maintain airflow efficiency. While convenient, it generally has a shorter lifespan and higher air leakage potential than rigid systems.

Other options include fiberglass duct board, offering good thermal and acoustic properties, and plastic ducts, often used for specific applications. UL 181 listed ducts and connectors, with plain ends, ensure compliance with safety standards. The choice of material depends on factors like budget, accessibility, HVAC system requirements, and the specific installation environment, as detailed in comprehensive installation instructions.

Sheet Metal Ductwork: Pros and Cons

Sheet metal ductwork, typically galvanized steel or aluminum, remains a popular choice for HVAC systems due to its inherent strengths. A significant pro is its durability; properly installed sheet metal systems can last for decades, resisting damage and maintaining structural integrity. It also offers excellent airtightness when correctly sealed, minimizing energy loss and maximizing system efficiency, as outlined in SMACNA duct design manuals.

However, sheet metal also presents challenges. Installation requires skilled labor for accurate fabrication and assembly, increasing labor costs. The rigidity of the material can make navigating complex building layouts difficult, potentially necessitating more fittings and increasing resistance to airflow. Noise transmission is another concern; without adequate insulation, sheet metal can amplify system sounds.

Furthermore, corrosion can be an issue, particularly in humid environments, although galvanized coatings offer some protection. Careful consideration of these pros and cons is crucial when determining if sheet metal is the appropriate material for a specific ductwork installation project.

Flexible Ductwork: Applications and Limitations

Flexible ductwork, often constructed with a wire helix and an inner liner, provides versatility in HVAC system installation, particularly in retrofits or buildings with complex geometries. Its primary advantage lies in its ease of routing around obstacles, reducing the need for numerous elbows and fittings. This simplifies installation and can lower material costs. The ADCAS recommends the new BSRIA guide to clarify confusion surrounding flexible ductwork.

However, flexible duct also has significant limitations. It inherently offers higher airflow resistance compared to smooth metal ducts due to its corrugated interior. This increased resistance can reduce system efficiency and increase energy consumption. Furthermore, flexible duct is more prone to leaks and damage if not properly supported and protected.

Its use should be limited to short runs and connecting rigid ductwork to registers. Overreliance on flexible duct can compromise overall system performance and longevity, emphasizing the importance of adhering to best practices and industry standards.

Duct Sizing and Static Regain

Proper duct sizing is crucial for an efficient HVAC system, ensuring adequate airflow to each room while minimizing energy waste. Incorrectly sized ducts can lead to noisy operation, uneven temperatures, and increased utility bills. The SMACNA HVAC Systems—Duct Design manual provides detailed methodologies for calculating appropriate duct dimensions.

The concept of static regain is central to effective duct design. Static regain refers to the recovery of static pressure as airflow velocity decreases in the ductwork. A well-designed system aims to balance velocity and static pressure, minimizing friction losses and maximizing airflow delivery.

Calculating duct sizes involves considering factors like airflow rate (CFM), duct length, and desired velocity. Methods include equal friction, static regain, and velocity reduction. Utilizing software or consulting with a qualified HVAC professional is recommended for complex systems to ensure optimal performance and adherence to industry standards.

HVAC System Compatibility

Ensuring compatibility between the new ductwork and the existing HVAC system is paramount for optimal performance and efficiency. Factors like the system’s BTU capacity, airflow requirements, and static pressure capabilities must be carefully considered during the installation process.

An undersized duct system can restrict airflow, causing the HVAC unit to work harder, potentially leading to premature failure and increased energy consumption. Conversely, an oversized system can result in short-cycling, reducing dehumidification and comfort levels.

When upgrading or replacing ductwork, it’s crucial to verify that the new system aligns with the HVAC unit’s specifications. Consulting the HVAC manufacturer’s installation manual and seeking guidance from a qualified installer are essential steps. Properly matched systems deliver consistent comfort, reduced energy costs, and extended equipment lifespan.

Essential Tools for Ductwork Installation

Successful ductwork installation requires a range of specialized tools to ensure precise cuts, secure connections, and proper sealing. Essential tools include sheet metal snips for cutting duct material, a seam sealer for airtight joints, and a foil tape dispenser for efficient application.

A duct cutter, whether manual or powered, is vital for creating clean, accurate cuts in round or rectangular ducts. A crimping tool is necessary for forming and shaping sheet metal, while a rivet gun secures duct sections together. Measuring tools like tape measures and levels are crucial for accurate layout and alignment.

Safety gear, including gloves, safety glasses, and a dust mask, is non-negotiable. Additionally, a vacuum with a HEPA filter helps maintain a clean work environment. Referencing a detailed installation guide and understanding each tool’s proper use is key to a professional and safe installation.

Safety Precautions During Installation

Prioritizing safety during ductwork installation is paramount. Always wear appropriate personal protective equipment (PPE), including safety glasses to shield against debris, gloves to protect hands from sharp edges, and a dust mask to prevent inhalation of particles. Working at heights necessitates fall protection, such as harnesses and secure scaffolding.

Be mindful of electrical hazards; always de-energize circuits before working near wiring. Sharp sheet metal edges pose laceration risks, demanding careful handling and the use of protective gear. Proper ventilation is crucial when using sealants or adhesives, following manufacturer’s instructions diligently.

When utilizing power tools, adhere to all safety guidelines and ensure proper grounding. A comprehensive installation guide should emphasize these precautions. Remember, if you lack confidence in performing a task safely, consult a qualified HVAC installer. Prioritize well-being throughout the entire process.

Planning the Ductwork Layout

Effective ductwork layout planning is crucial for optimal HVAC system performance. Begin by analyzing the building’s floor plan, identifying areas requiring heating and cooling. Consider the location of the HVAC unit and plan the main trunk lines for efficient airflow distribution. Minimize duct length and bends to reduce static pressure loss, referencing SMACNA duct design manuals for guidance.

Strategic placement of supply registers and return grilles ensures balanced air distribution throughout the space. Account for obstructions like walls, ceilings, and existing structures. A well-planned layout minimizes noise and maximizes comfort. Utilize a ductwork installation guide to visualize the system and identify potential challenges.

Prioritize accessibility for future maintenance and cleaning. Proper planning, informed by resources like BSRIA guides, is fundamental to a successful and efficient installation.

Calculating Ductwork Dimensions

Accurate ductwork dimensioning is vital for maintaining proper airflow and system efficiency. Calculations begin with determining the required airflow (CFM – cubic feet per minute) for each room, based on its size and heat load. Utilize the static regain method, as outlined in SMACNA HVAC Systems – Duct Design manuals, to size duct runs effectively.

Consider duct velocity – typically between 700-900 feet per minute for main runs and 500-700 feet per minute for branch ducts. Friction rate, influenced by duct material and length, must also be factored in. Employ duct sizing charts or software to translate airflow requirements into appropriate duct diameters or rectangular dimensions.

A ductwork installation guide should provide detailed instructions and formulas. Proper sizing prevents excessive noise, energy waste, and system imbalances. Referencing BSRIA guides can clarify complex calculations and ensure compliance with industry standards.

Installing Main Trunk Lines

The installation of main trunk lines forms the backbone of your HVAC system. Begin by securely supporting the ductwork with appropriate hangers and bracing, adhering to local building codes. Ensure proper alignment and slope for condensate drainage, especially in horizontal runs.

When using sheet metal ductwork, carefully join sections using approved methods like duct tape, mastic sealant, or mechanical fasteners, ensuring airtight seals. For flexible duct, avoid sharp bends and kinks, maintaining a smooth, gradual curvature. A ductwork installation guide emphasizes the importance of minimizing restrictions to airflow.

Regularly check for levelness and stability as you progress. Refer to the CLIMAVER Installation Manual for specific guidance on their systems. Remember, a solid foundation with well-installed trunk lines is crucial for optimal system performance and longevity. Prioritize safety and follow all manufacturer’s instructions.

Connecting Branch Ducts

Connecting branch ducts to the main trunk lines requires precision to maintain airflow balance and efficiency. Utilize properly sized take-offs and dampers to regulate airflow to individual rooms or zones. Securely fasten branch ducts using screws, rivets, or approved duct tape, ensuring airtight connections.

When transitioning between different ductwork materials – for example, from metal trunk lines to flexible branches – employ appropriate transition fittings. Avoid abrupt changes in duct diameter, as these can create turbulence and reduce system performance. A ductwork installation guide stresses the importance of smooth transitions.

Carefully seal all joints and seams with mastic sealant or foil tape to prevent air leakage. Refer to SMACNA standards for best practices in duct sealing. Remember, even small leaks can significantly impact HVAC system efficiency. Prioritize airtight connections for optimal comfort and energy savings.

Sealing Ductwork for Optimal Efficiency

Effective duct sealing is paramount for maximizing HVAC system efficiency and indoor air quality. Air leaks within the ductwork can lead to significant energy loss, increased utility bills, and uneven temperature distribution throughout the building. A comprehensive ductwork installation guide emphasizes meticulous sealing practices.

Utilize mastic sealant, specifically designed for ductwork, along all joints, seams, and connections. Foil tape can be used for reinforcing, but should not be the primary sealant. Avoid using duct tape, as its adhesive degrades over time. SMACNA standards provide detailed guidance on approved sealing methods.

Inspect all connections thoroughly, paying close attention to areas where ducts intersect or transition. Pressure testing the duct system after sealing can identify any remaining leaks. Addressing these leaks ensures optimal airflow and minimizes energy waste. Remember, a well-sealed duct system contributes to a more comfortable and cost-effective home.

Insulating Ductwork to Prevent Heat Loss

Proper ductwork insulation is crucial for maintaining consistent temperatures and reducing energy consumption. Insulating ducts minimizes heat loss in winter and heat gain in summer, improving HVAC system efficiency. A detailed ductwork installation guide stresses the importance of selecting the appropriate insulation material and applying it correctly.

Consider the climate and location of the ductwork when choosing insulation. Options include fiberglass, duct wrap, and spray foam. Ensure the insulation’s R-value meets local building codes and energy efficiency standards. Seal all seams and joints in the insulation with foil tape to prevent air infiltration.

Pay particular attention to insulating ducts located in unconditioned spaces, such as attics, crawl spaces, and garages. Properly insulated ducts contribute to a more comfortable indoor environment and lower utility bills. Refer to SMACNA guidelines for specific insulation recommendations and best practices.

Air Diffusion Supply Duct Systems

Air diffusion supply duct systems represent a modern alternative to traditional HVAC setups utilizing conventional vents, registers, and diffusers. These systems are designed for enhanced air distribution and improved building performance, as highlighted in various ductwork installation guides. They offer a streamlined approach to delivering conditioned air throughout a space.

Compared to traditional methods, air diffusion systems often feature fabric-based ducts or specialized linear diffusers. These components promote a more even airflow, reducing hot and cold spots. This technology can lead to increased comfort and energy savings. Proper installation, following manufacturer’s instructions and industry standards, is paramount for optimal functionality.

When considering an air diffusion system, consult with a qualified HVAC installer to assess its suitability for your specific building and climate. Understanding the system’s design principles and installation requirements, as outlined in relevant guides, ensures a successful and efficient outcome.

UL 181 Listed Ductwork: Standards and Compliance

Ensuring ductwork meets industry standards is crucial for safety and performance. UL 181 listing signifies that nonmetallic air ducts and connectors have undergone rigorous testing by Underwriters Laboratories (UL). This certification, under file numbers like MH9596 and 9844, confirms the materials meet specific requirements for fire resistance and structural integrity.

Compliance with UL 181 is often a requirement for building codes and insurance regulations. Utilizing listed ductwork provides peace of mind, knowing the system has been evaluated for potential hazards. Installation instructions for UL 181 listed products must be strictly followed to maintain the listing’s validity.

A comprehensive ductwork installation guide should always emphasize the importance of verifying UL listing before selecting materials. Proper installation, coupled with compliant materials, contributes to a safe and efficient HVAC system. Referencing the UL directory and manufacturer’s specifications is essential for adherence to standards.

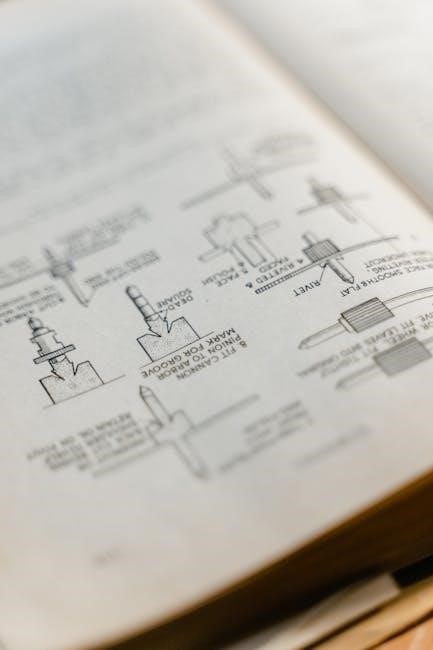

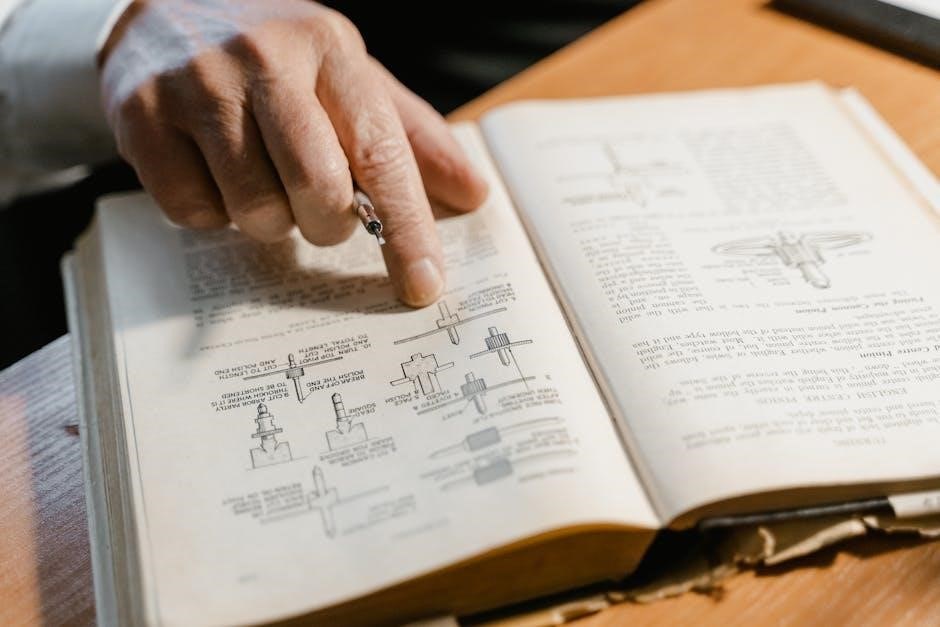

CLIMAVER Installation Manual Overview

The CLIMAVER Installation Manual provides detailed guidance for working with their specific ductwork systems. It emphasizes mastering construction techniques through understanding the phases of manual fabrication. This handbook is designed to streamline the installation process, offering a practical approach to achieving optimal results.

A key component of the manual focuses on calculating the square meterage of CLIMAVER ductwork needed for a project, ensuring accurate material ordering and minimizing waste. The manual highlights the ease and speed of installation, positioning CLIMAVER as a user-friendly solution for HVAC professionals.

A thorough ductwork installation guide should reference resources like the CLIMAVER manual for system-specific details. Understanding the manufacturer’s recommendations is vital for maintaining warranty coverage and ensuring long-term system reliability. Proper adherence to the manual’s instructions contributes to a high-quality, efficient installation.

Finding a Qualified HVAC Installer

Successfully navigating ductwork installation often requires the expertise of a qualified HVAC installer. If you lack confidence in performing the work yourself, or encounter complex issues, professional assistance is crucial. A skilled installer ensures adherence to local codes, proper system sizing, and optimal performance.

When selecting an installer, verify their licensing and insurance. Seek recommendations from trusted sources and check online reviews. A reputable contractor will provide detailed quotes, explain the installation process clearly, and address any concerns you may have. They should also be familiar with relevant ductwork installation guides and industry standards like those from SMACNA.

Remember, a poorly installed HVAC system can lead to energy inefficiency, reduced comfort, and costly repairs. Investing in a qualified installer is a long-term investment in your home’s comfort and efficiency. Don’t hesitate to ask about their experience with CLIMAVER systems or UL 181 compliance.

Resources and Further Reading (SMACNA, BSRIA Guides)

For in-depth knowledge and best practices in ductwork installation, several resources are invaluable. The Sheet Metal and Air Conditioning Contractors’ National Association (SMACNA) provides comprehensive HVAC Systems—Duct Design manuals, detailing design, fabrication, and installation procedures. These are considered industry benchmarks.

The Building Services Research and Information Association (BSRIA) offers guides, including recent publications clarifying flexible ductwork applications and improving building performance. These resources address common misconceptions and promote efficient system design. Accessing these guides can significantly enhance understanding.

Furthermore, manufacturers like CLIMAVER provide detailed installation manuals specific to their products, ensuring proper implementation and adherence to safety standards. UL 181 listing information, available online, confirms ductwork meets stringent safety and performance requirements. Utilizing these resources ensures a compliant and effective installation.